Conveyor belt systems are an integral part of modern industry, allowing for the efficient transport of goods and materials across production facilities, warehouses, and shipping terminals. The history of conveyor belt systems is a fascinating one, spanning centuries of innovation and development.

The Appearance of Conveyor Systems

The first conveyor belt systems date back to the 18th century when wooden belts were used in mines to transport bulk materials such as coal and ore. These early systems were simple and primitive, consisting of a series of wooden slats or belts that were pulled by hand or by animals.

In the early 19th century, the first conveyor belts made of leather were introduced, which were much more durable than the earlier wooden belts. These early conveyor belts were still manually operated, but they allowed for greater efficiency and productivity in the mining industry.

The Appearance of Automated Conveyor Systems

The first automated conveyor belt system was developed in the late 19th century by Richard Sutcliffe, a British engineer. Sutcliffe’s system used a series of belts that were driven by a central motor, allowing for greater control and precision in the movement of materials.

Developments

The early 20th century saw further developments in conveyor belt technology, including the introduction of rubber belts in the 1920s. Rubber belts were more durable and could handle heavier loads than leather belts, and they were also more resistant to the harsh conditions of industrial environments.

In the 1940s, conveyor belt systems became even more automated with the introduction of electric motors and automated controls. These systems allowed for greater efficiency and productivity in manufacturing and transportation, as materials could be moved quickly and easily without the need for manual labor.

The post-war era saw continued innovation in conveyor belt technology, with the introduction of new materials such as nylon and polyester. These materials were lighter and more flexible than rubber, allowing for greater flexibility and versatility in conveyor belt design.

In the 1960s and 1970s, computer technology revolutionized the manufacturing industry, and conveyor belt systems became even more sophisticated. Automated controls and sensors allow for greater precision and accuracy in the movement of materials, while computer-aided design (CAD) and simulation software allowed for more efficient and cost-effective conveyor belt design.

The 1980s and 1990s saw further advances in conveyor belt technology, including the introduction of modular belt systems and the development of more advanced automated controls. Modular belt systems allowed for greater flexibility and customization in conveyor belt design, while advanced controls and sensors allowed for even greater precision and efficiency in material handling.

Modern Conveyors

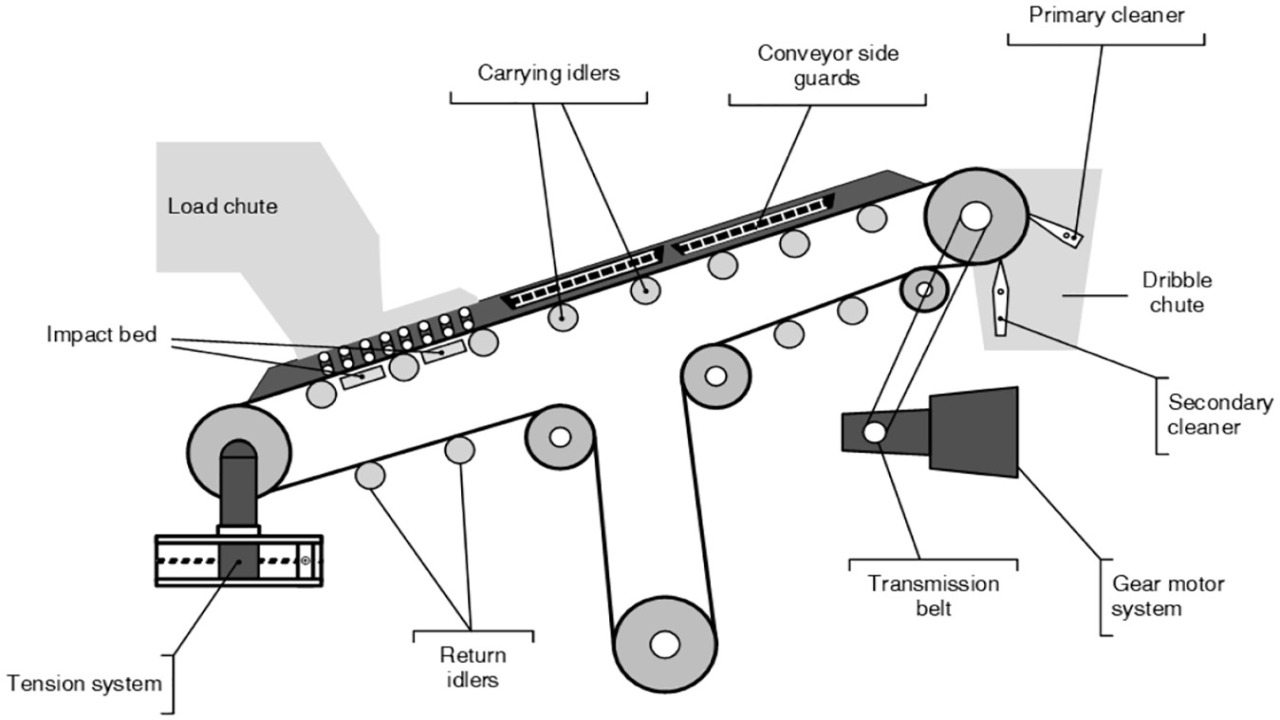

Today, conveyor belt systems are used in a wide range of industries, from manufacturing and transportation to mining and agriculture. They come in a variety of shapes and sizes, from simple roller conveyors to complex systems that can handle large volumes of materials over long distances.

The latest innovations in conveyor belt technology include the use of advanced sensors and machine learning algorithms to optimize the movement of materials and improve overall efficiency. For example, some conveyor belt systems are equipped with sensors that can detect the weight and volume of materials, allowing for more precise and efficient handling.

Conclusion

In conclusion, the history and evolution of conveyor belt systems are a testament to human ingenuity and innovation. From the earliest wooden belts to the latest high-tech systems, conveyor belts have played a crucial role in the growth and development of the modern industry. As technology continues to advance, we can expect to see even more sophisticated and efficient conveyor belt systems in the years to come.